Factory price & fast delivery

Recommend best suitable product for you

OEM/ODM service

One year warranty service

Straight-tooth drive is widely used and can replace the rotating structure of inner and outer toothed turntable bearings and pinion gears. The integrated full-protection design is more convenient and has advantages.

We have designed three standard series of small load, medium load and large load. However, due to the peculiarities of some industries and machinery, these three standard series are not necessarily suitable. Therefore, we can also customize Spur Gear Drive Customized according to different hosts and operating conditions, and design more suitable non-standard products.

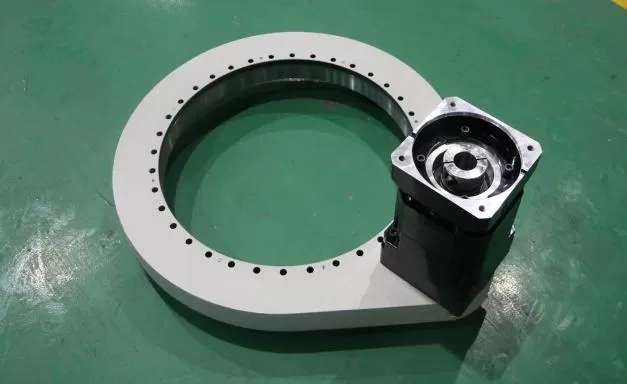

1.Customized double-gear high-precision, negative-clearance precision helical (grinding) slewing drive, to achieve zero backlash for customers.

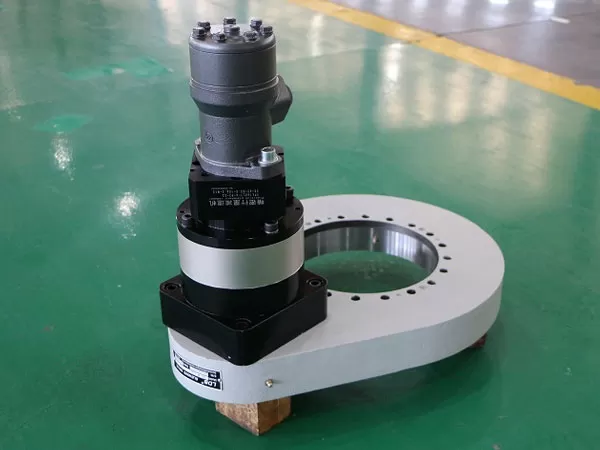

2.It is equipped with customized non-standard high-precision spur gear (grinding gear) slewing drive, supporting planetary reducers and motors for customers.

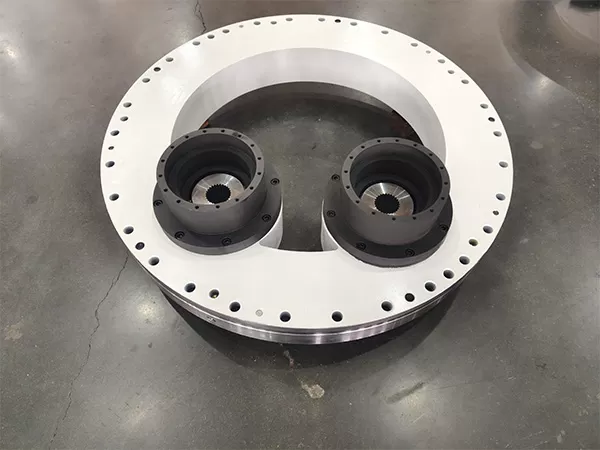

3.Customized large load capacity, high output torque, precision helical gear (grinding gear) rotary drive, to solve the load bearing problem of the machine tool turntable for customers.

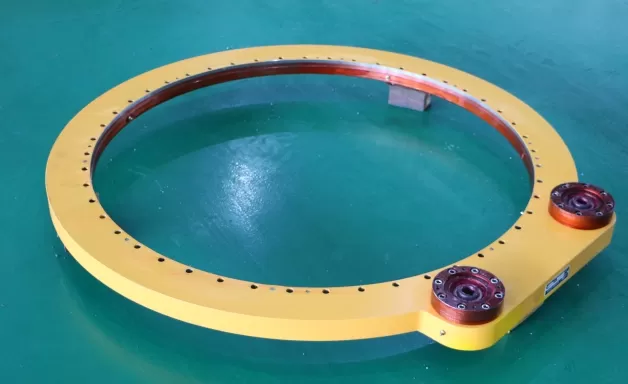

4.Customized internal teeth, full protection, and integrated mounting base plate can reduce the size of the equipment for customers, save costs, and save installation and commissioning time.

5.This spur gear slew drive is designed according to the non-standard requirements of Canadian customers. The product has high precision, high speed, compact structure, and is suitable for top rotary support of special vehicles.

6.This custom product is customized for a US customer, is used on the turntable of stone cutting equipment. The internal gear structure saves installation space and offers a rotational accuracy of ≤0.1°. The large rolling element size provides increased load capacity, with a rated axial static load of 2500kN.

Chat Online

Get A Quote