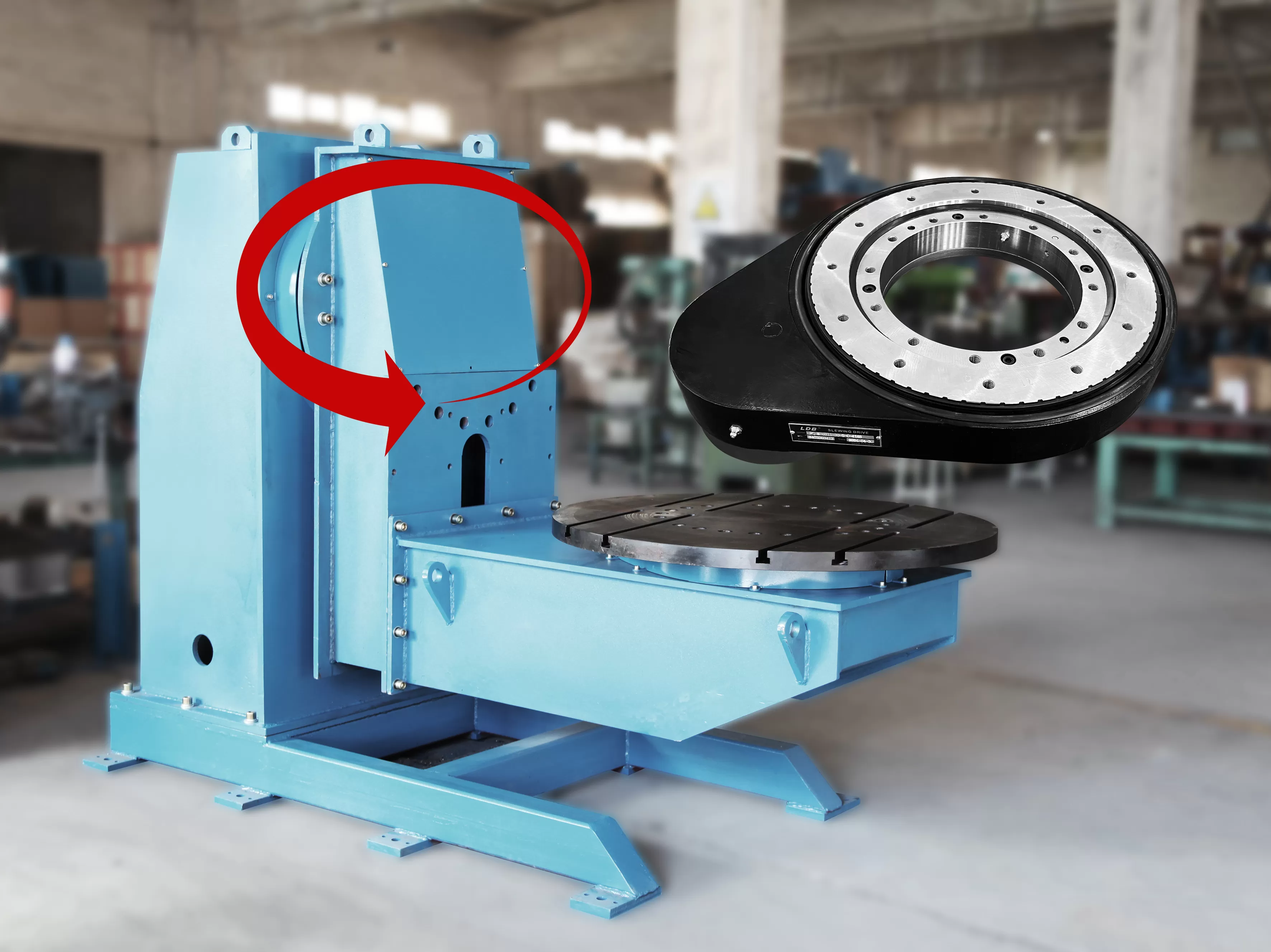

In the field of precision mechanical processing, the positioner is a key auxiliary device for achieving multi-face workpiece machining and improving processing efficiency. Its tilting accuracy, load-bearing capacity, and operational stability directly determine the machining accuracy of workpieces and the continuous operation efficiency of production lines. As the core transmission component of positioners, the spur gear slew drive precisely meets the stringent requirements of machine tool machining by virtue of its core advantages of high transmission accuracy, strong heavy-load adaptability, and high reliability, serving as a key support for enabling efficient production in precision machining.

The spur gear slew drive adopts a high-precision tooth profile design and precision gear grinding technology to reduce gear meshing backlash, ensuring positioning accuracy at any angle and satisfying the stringent requirements for workpiece angular positioning in precision machining. Whether it is multi-station switching for complex curved surface machining or precise alignment of symmetrical components, it can achieve stable and reliable power transmission and positioning.

Chat Online

Get A Quote