In semiconductor packaging and testing lines, the die insertion machine is a key device that enables precise alignment between chips and carriers. Its operational accuracy and speed directly determine the yield rate of chip packaging and the efficiency of the production line.

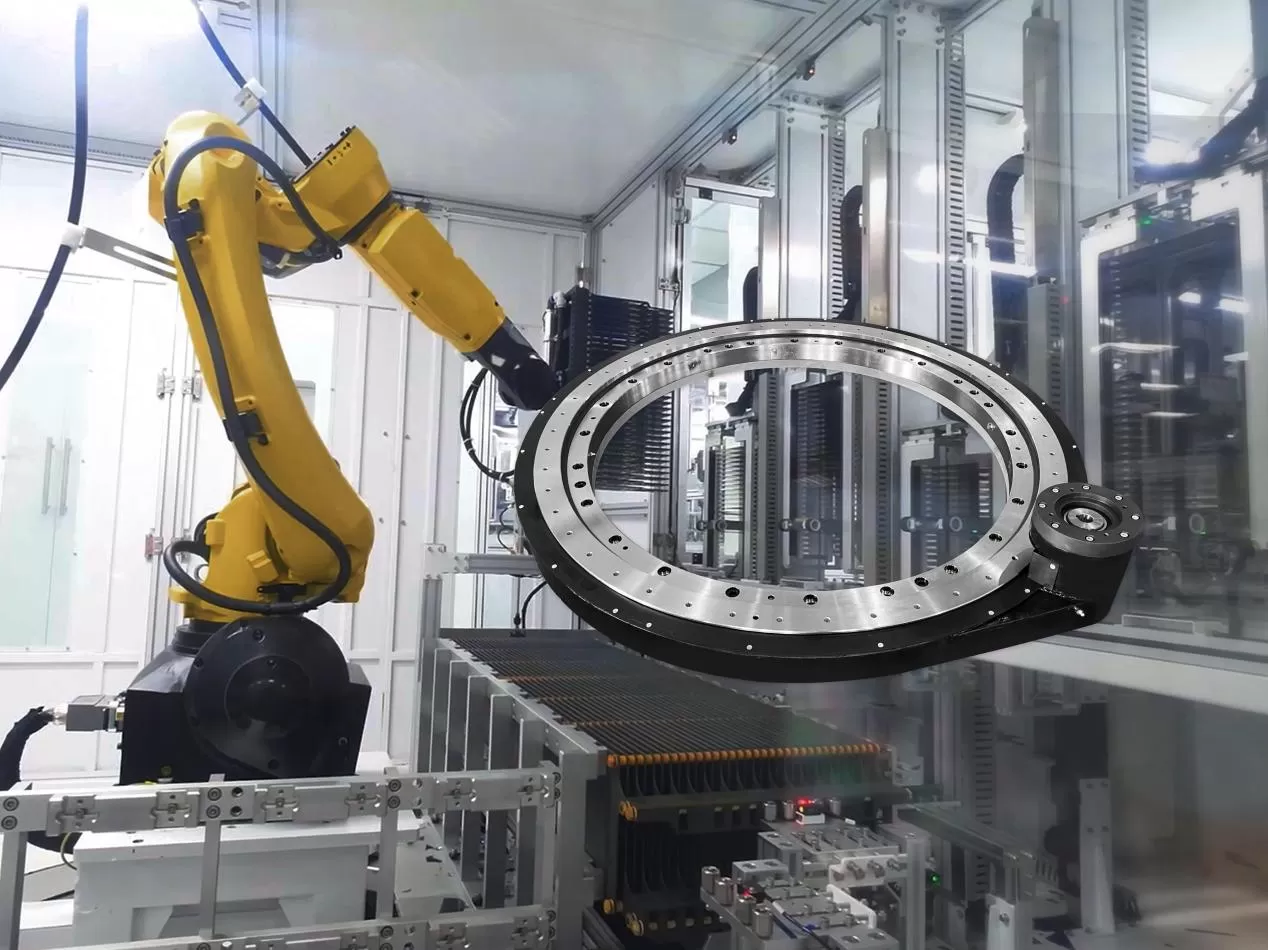

The spur gear slew drive adopts a small-module tooth profile design combined with precision gear grinding technology, with the gear meshing backlash controlled within 0.01 mm. Coupled with an encoder, it achieves high-precision positioning of the die insertion station.

Compared with worm gear transmission, gear transmission offers higher speed, enabling the spur gear slew drive to reach a maximum rotational speed of 30 rpm — a 40% increase in speed compared with traditional transmission components. This performance allows the die insertion station to rapidly complete chip pick-and-place, rotation, and alignment actions, significantly boosting the hourly output of the production line.

Chat Online

Get A Quote